We saw Serbia as a country with good strategic position, adequate infrastructure and great human resource potential. Being at a unique position in the European market, Serbia offers diverse possibilities and, above all, high quality workmanship.

Over the past ten years, Serbia was one of leading European destinations for foreign investments in the automotive industry.

The development of automotive sector in Serbia goes back to 1939, when assembly of military trucks started in the City of Kragujevac, today the heart of Serbian automotive industry.

Ever since then, by acquiring the license from FIAT, the small Kragujevac plant was transformed into the Serbian car-producing giant called Zastava. In the next 55 years, Zastava would go on to produce more than 4.5 million vehicles, 650,000 of them designated for export.

Most significantly, the year 2008 saw the takeover of lumbering Zastava factory by FIAT with an unprecedented investment project worth €940 million. The factory was completely overhauled with new machinery being introduced for the production of the brand new FIAT 500L mini MPV.

As the only passenger cars producer in Serbia at present, FIAT is the backbone of the automotive industry.

Nevertheless, what forms the meat on the bones, are the components and systems suppliers. Being a latecomer in the foreign investments game it took some time before large investors started considering Serbia as a viable location.

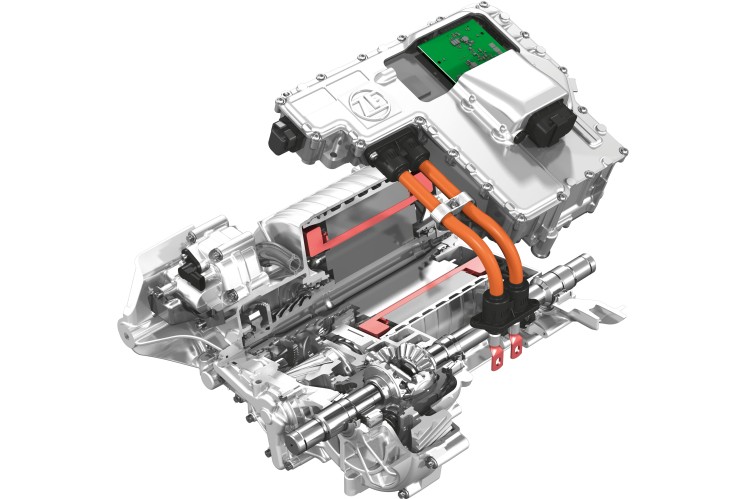

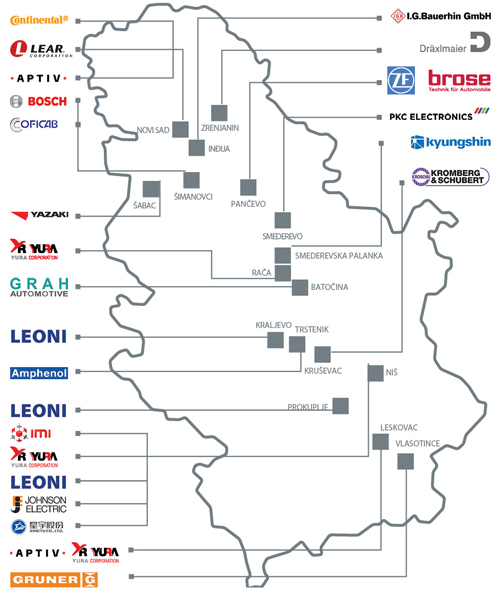

As expected, first to come were very labor intensive low value added producers in wiring harness and seat covers. These were gradually replaced by more high end oriented companies like Bosch, Continental, ZF, Brose, Michelin and Johnson Electric.

With motor vehicles becoming an electronics product as much as mechanical, production of these systems is becoming dominating force driving the new investments.

Currently the major product groups in Serbian automotive industry are:

• Tires

• Wiring harness

• Wipers

• Hoses

• Various metal components.

Given the current investment trends, these will be replaced in the future by products such as electric motors, turbochargers, radar and optical sensors, electronics and power converters.

It is the time of industry 4.0 and emerging technologies. Engineering is a tough profession and the world cannot seem to get enough of engineers these days.

Three largest cities in Serbia also represent the three largest centers for technical education.

• The biggest one is in the capital - Belgrade. There, the tradition of Faculty of Mechanical Engineering and Faculty of Electrical Engineering is supplemented by Traffic and Logistic, Organizational Sciences and Metallurgy, comprising the largest and most diversified engineering pool in Serbia.

• Novi Sad Faculty of Technical Sciences is famous for focusing on trendy areas such as software development and mechatronics.

• The University in Niš, Serbia’s third largest city, is renowned for being the hub for electronics.

• Kragujevac University is strong in mechanical engineering

• Smaller technical faculties are also found in Zrenjanin, Čačak, Kraljevo and Novi Pazar.

The eight tech-u centers in Serbia are generating over 7,000 engineers yearly, with their preferred specialization: mechatronics, electronics, manufacturing, IC engines, ICT, quality management or aeronautics.

The trend of investments into R&D activities by multinational companies is pretty recent, because Serbia needed to prove itself as fruitful ground for complex manufacturing activities first. However, it is the top-notch industry leaders like Continental, Bosch, ZF or Brose that are pioneering these investments, and with their positive experience, the government is already planning to boost its investments into educational institutions.

The strategy of the Serbian Government is to go for more high-end products, with more know-how and value added. These type of investments require primarily skilled operators and good infrastructure to support.

• To tackle this challenge we have identified the towns in Serbia with highest output of technicians of mechanical and electronics background which we are suggesting as the „high tech manufacturing“ map.

• To boost the effectiveness of technical schools, Serbia has since 2018 introduced the system of dual education, based on German model, allowing secondary technical school students to spend 3 days in classroom and 2 days in the real factory. It is a significant step in bringing educational and real sector closer together, most welcomed by employers.

If all of these efforts are bearing fruit it can be recognized through significant “capital-intensive” investments made in recent years that are encompassing state of the art manufacturing systems and high tech products.

To name just some of them the new ZF E-mobility factory in Pančevo produces electric motors, generators for hybrid and electric drives while the new plant of German - Hong Kong based BMTS Technology in Novi Sad is the OEM supplier of next generation turbochargers for customers such as PSA, VW and BMW.

Further large-scale investments in technology were made by companies such as Chinese Mei Ta building the largest automotive parts foundry in the Balkans, Robert Bosch plant for wiper systems or the factories specializing in production of electric motors for automotive applications by leaders such as Hong Kong Johnson Electric or German Brose.

One of the more important product of automotive industry in Serbia are the tires with Michelin and Cooper Tires plants in Pirot and Kruševac, soon to be supplemented by factories of Chinese Linglong and Japanese Toyo Tires.

The last, but not the least, peace of our puzzle are components suppliers. By the nature of their size, these companies are mostly part of SME sector, and unlike with the large system suppliers there is a strong presence of local Serbian companies among them.

This segment addresses the Tier2 and further part of the chain, with companies that will take care of stamped, pressed injected, forged, casted, machined and such elements. While it may be that they make the smallest mark in terms of value, they are the base that makes production of complex systems possible.

This is why RAS pays special attention to this sector, as it is seen as integral part for development of local competences, while increasing the value added of Serbian made products and creating more attractive environment for investments.

RAS Suppler Development Program is aimed at providing expert consultancy in different enterprise management fields, while also financially supporting the investments into machinery and equipment. The program is tailor made to fit the SME sector and overseen by advisory board of large multinationals.

To support further development of this segment, RAS is also encouraging foreign companies to consider joint-venture agreements with local Serbian suppliers that could produce synergies and broaden the market perspective of both.